PRINCIPLE

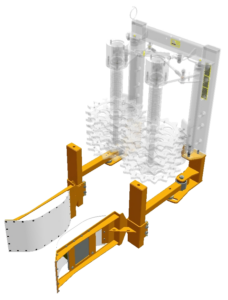

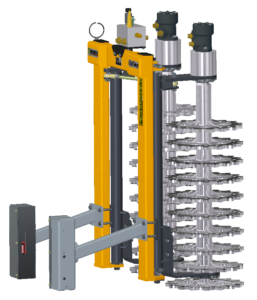

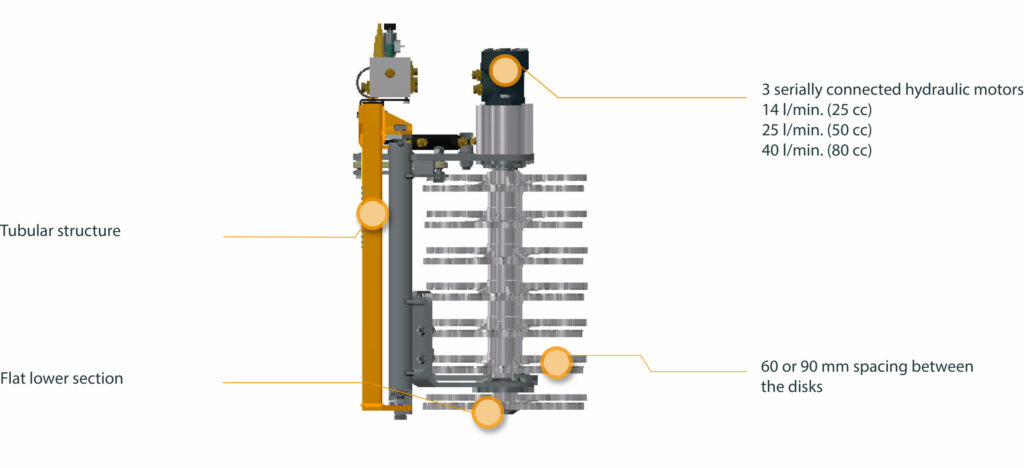

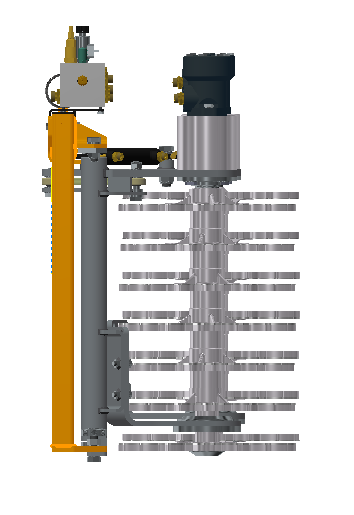

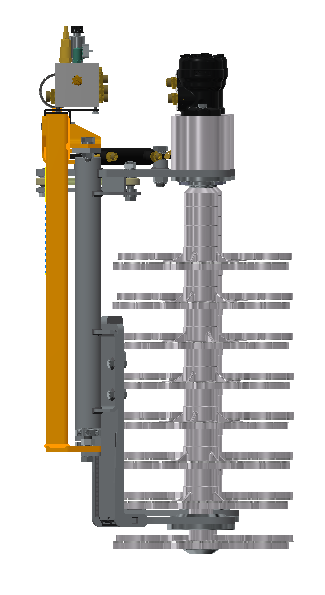

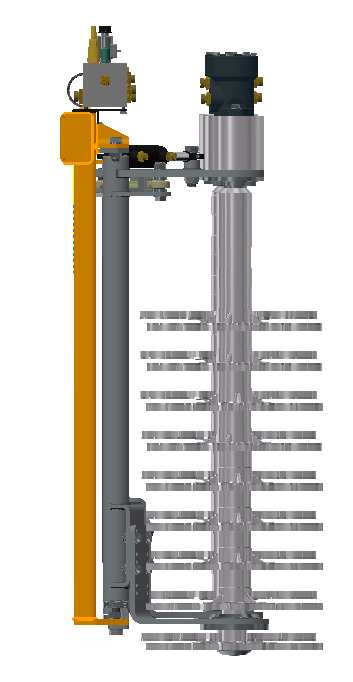

- A frame with two disc modules equipped with blades performing a shear cut. The discs are driven by 2 hydraulic motors. All pre-pruner functions are centralized in a hydraulic block.

- Cutting modules opening and closing is controlled by a control switch.

- Working speed up to 10 km/h.

- Available with a stack of 6 to 24 disks with an interval of 60 or 90 mm.

TECHNICAL SPECIFICATIONS

RANGE

Narrow-wide spaced

MODEL

MP 122

FLOW RATE

24 to 40 l/min

SPEED OF ROTATION

280 trs/min

WEIGHT

145 to 290 kgs

MODELS

SHORT FRAME

SHORT FRAME +

LONG FRAME

ADVANTAGES

- The shape of the disc ensures a good grip on the vine shoots and a regular feeding of the machine, without damaging the tying wires.

- The 60 mm interval between the disks furthers the cleaning of the tying wires thanks to the cutting sections mounted on a carrier disk whose thickness prevents the wire from penetrating between the teeth of the cutting sections.

- Reduced maintenance, lightweight and low flow rate.

- Reduced projections thanks to a low rotational speed.

- The bottom section of the discs is totally flat, preventing any stripping of the spurs.

SHARP DISK

- A circular disk with a sharp edge on one of the cutting modules, facing a toothed disk on the other module, ensures a clean sharp cut, without cracking of the wood. The cutting effect of the disk avoids pinching the wood, which is a common phenomenon in shear cutting. A specific configuration of this equipment ensures the respect of the environment (posts and tying wires).

OPTIONS

AUTOMATIC OPENING

- The optical detection operates for any type of post (wood, steel, concrete). There must be no leaves left. The system requires posts without holes in the reading axis and with a cross-section larger than or equal to 25mm.

- The inductive detection only operates with steel posts. But it allows pre-pruning immediately after the harvest, even if there are leaves.